GCTDrill

Experience the drill bit that can be used for 24hrs without change

Using super hard tungsten carbide steel from Switzerland combined with GCT ultra-precision multilayer CVD coating technology (alternating nano-polycrystalline layer coating and polycrystalline layer coating), we are able to produce GCT MicroSpeed Coating with hardness that is comparable to the hardness of natural diamond. Our CVD coating is able to withstand high temperature of 800 degrees and its strong adhesion ensures no peel off even when there is considerable wear on the tool. CVD coating will not be affected during high-speed processing, thereby effectively reducing tool wear during drilling, improving process capability and hole count, ensuring stable machining quality.

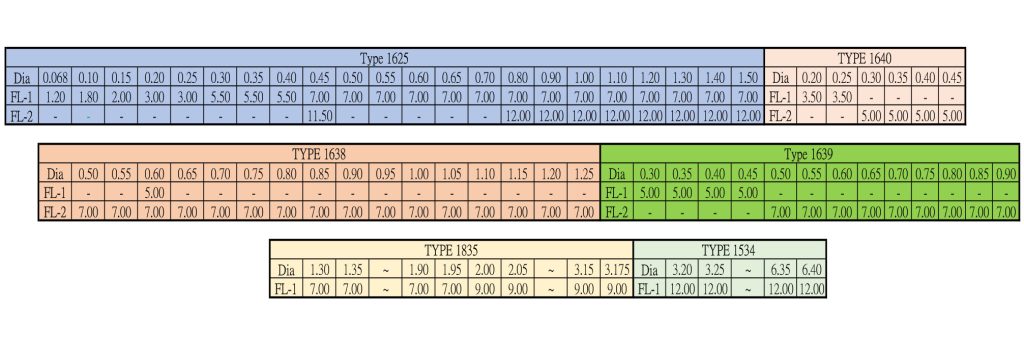

DRILL LIST

CVD ROUTER - TOOL TYPES

1625 Undercut Drill (Thick Coating)

Suitable for drilling glass, quartz, technical ceramics such as Al2O3, AlN, ZrO2, SiC and Silicon.

1638 Undercut Drill

Suitable for drilling IMS, aluminium, copper, laminate with ceramic fillers and high Tg material ≥200℃ such as RO4xxx, Arlon 25x, Isola IS 620

1639 Undercut Drill (5G material)

Suitable for drilling 5G materials

1640鑽針

Suitable for drilling halogen-free material, laminate with fillers and high Tg material ≥150℃

1835 Straight Type Drill

Suitable for drilling IMS, aluminium, copper, laminate with ceramic fillers and high Tg material ≥200℃ such as RO4xxx, Arlon 25x, Isola IS 620. Suitable for drilling glass, quartz, technical ceramics such as Al2O3, AlN, ZrO2, SiC and Silicon.

1534 Inverse Diameter Drill

Suitable for drilling IMS, aluminium, copper, laminate with ceramic fillers and high Tg material ≥200℃ such as RO4xxx, Arlon 25x, Isola IS 620. Suitable for drilling glass, quartz, technical ceramics such as Al2O3, AlN, ZrO2, SiC and Silicon.

159X Countersink with 5 flutes

Suitable for chamfering of holes and contours in IMS and PCBs.